EPS ( Expanded Polystyrene ) surfboards are becoming apart of the range, with more of the team and customers ridding them. Expanded Polystyrene (EPS) is a light weight cellular plastic material consisting of small hollow spherical balls. Air trapped in these balls results in an extremely lightweight material, as it is comprised of ~95% air. These characteristics make EPS ideal for use in small wave boards like fish’s, rockets and short boards as more buoyancy helps to float you, added with the light weight of the board allows more maneuverability in weak conditions.

We’ve designed our EPS model surfboards with a centre wood stringer for a familiar feel to a normal PU surfboard. Glassed with epoxy resin which incorporates a new (patented) venting technology which releases built up gas, greatly reducing the chance of delaminating, EPS offers a lively, responsive feel which is especially helpful in small waves. The lightweight core results in a touch more buoyant ride than a standard polyurethane board, so you can ride slightly reduced or your regular dimensions.

Built on an extruded polystyrene (closed cell Styrofoam) blank, which does not absorb water even if dinged, provides a light weight core. Another plus for EPS is that it’s a recyclable material. EPS is a light, durable “epoxy” performance alternative to both the; regular weight; & super high performance boards.

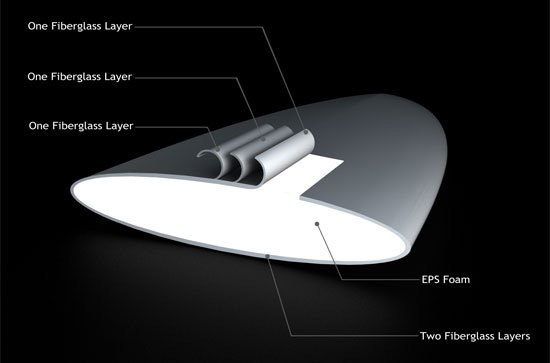

Built using the latest in EPS/Epoxy materials; the XF technology combines a light weight EPS core with Biaxial Fibreglass Cloth and Epoxy Resin: Biaxial Fibre Glass has about half of its fibres aligned along the length of the cloth (0 degrees) and about half across the cloth (90 degrees) lending itself as a perfect option for creating a controlled flex pattern. Expanded Polystyrene (EPS) foam is a version of polystyrene foam typically found in the core of Firewire surfboards.

EPS is typically the lightest of the three foams used in surfboard construction resulting in a much lighter board translating to increased buoyancy and floatation. Basically the lowest density or lightest board will float you the best! The advantage of better buoyancy is added paddling speed and increased manoeuvrability allowing you to ride a smaller board. EPS foam core is also less likely to deteriorate over time! Epoxy Resin is a healthier alternative to polyester as epoxy emits 50-75% fewer VOCs (volatile organic compounds) than polyester resin, which means a decrease in harmful chemicals in the shop and the environment in general. In fact, epoxy is a common household item, safe to use without a mask and with only moderate ventilation. Epoxy is lighter than polyester. Under most circumstances, resin makes up a large part of a completed board’s overall weight. Not only is epoxy lighter than polyester, but less is needed per coat. This ends up meaning a lighter surfboard – a big plus for most surfers. The biggest bonus However is the durability and strength of epoxy resin. All XF boards are constructed using a 36gram EPS core with a high-grade timber stringer, each board is hand laminated using epoxy resin and biaxial fibreglass on the deck providing a lighter, stronger board that feels fast and responsive under your feet increasing performance in a wide variety of conditions!